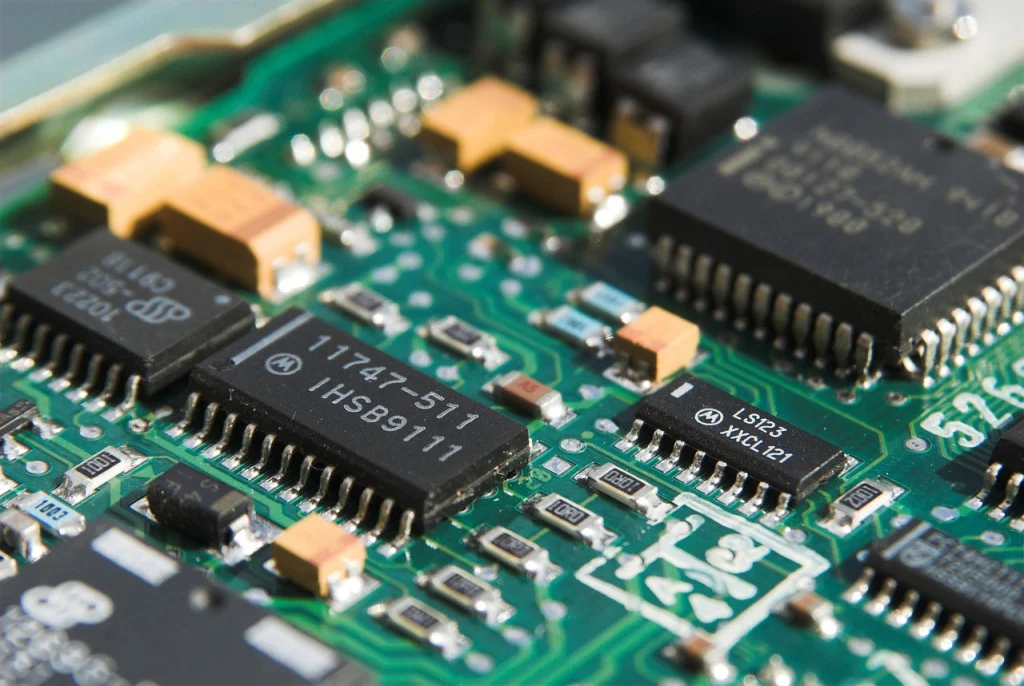

BS 9000 Electronic Components Package

BS 9000 is a British standard that provides guidelines for quality management systems in electronic components. The standard was first published in 1989 and was revised in 1995. It is currently being revised again to align with ISO 9001:2015, which is the international standard for quality management systems.

The BS 9000 standard provides a framework for managing quality in the manufacture and supply of electronic components. It covers all stages of the product lifecycle, from design and development through to production, testing, and delivery. The standard is applicable to all types of electronic components, including passive components, active components, and electromechanical components.

The BS 9000 standard is aimed at manufacturers, distributors, and suppliers of electronic components, as well as their customers. It provides a common language and set of guidelines for managing quality, which helps to reduce the risk of errors and defects, and improves overall customer satisfaction.

The BS 9000 standard is based on a set of principles that are common to all quality management systems. These principles include customer focus, leadership, engagement of people, process approach, improvement, evidence-based decision making, and relationship management.

The standard provides a framework for implementing these principles in the context of electronic components. It includes guidelines for planning, implementing, and maintaining a quality management system, as well as for monitoring and measuring performance and making continuous improvements.

Components of the BS 9000 standard

One of the key components of the BS 9000 standard is the electronic components package. This package provides guidelines for managing the quality of electronic components throughout the product lifecycle. It covers all stages of the process, from design and development through to production and testing.

The electronic components package includes guidelines for product design and development, including the use of simulation and modeling tools to optimize performance and minimize the risk of errors and defects. It also includes guidelines for testing and validation, including the use of statistical techniques to ensure that components meet or exceed the required specifications.

Another important component of the BS 9000 standard is supplier management. The standard provides guidelines for selecting and managing suppliers of electronic components, including the use of performance metrics to monitor and evaluate supplier performance.

The BS 9000 standard also includes guidelines for managing non-conforming products. It provides a framework for identifying and addressing issues with electronic components, including the use of corrective and preventive actions to reduce the risk of future errors and defects.

Overall, the BS 9000 standard provides a comprehensive framework for managing quality in the manufacture and supply of electronic components. It helps to ensure that components meet the required specifications and are delivered to customers on time and on budget. By implementing the standard, organizations can improve customer satisfaction, reduce the risk of errors and defects, and improve overall business performance.